The Three Main Services of IECQ Certification

Ą@

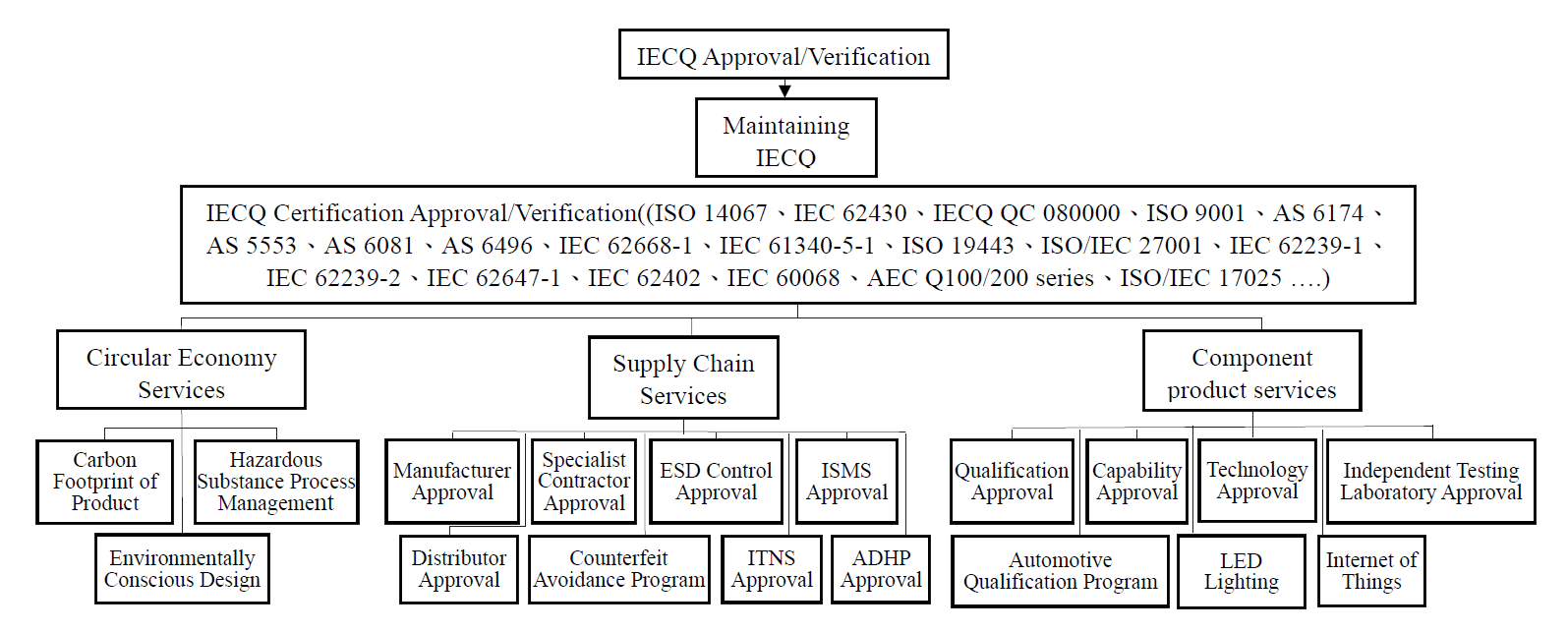

I. The Three Main Services of IECQ Certification:

There are three main services of IECQ certification. The first service is circular economy services including the carbon footprint of product (CFP) verification, environmentally conscious design (ECD) approval and hazardous substance process management (HSPM) approval. The second services is supply chain services including the manufacturer approval (MA), distributor approval (DA), specialist contractor approval (SA), counterfeit avoidance program (CAP) approval, electrostatic discharge (ESD) approval, important to nuclear safety (ITNS) approval, information security management system (ISMS) approval and aerospace defense and high performance (ADHP) approval. While the third service is component product services including the qualification approval (QA), capability approval (CA), technology approval (TA), automotive qualification program (AQP) approval, light emitting diode (LED) lighting approval, internet of things (IoT) approval and independent testing laboratory (ITL) approval. The certification service and its corresponding certification standard is listed as belowĄG

1 Circular Economy Services

a. Carbon footprint of

product (CFP) verification- ISO 14067, IECQ 03-2.

b. Environmentally conscious design (ECD) approval -

IEC 62430, IECQ 03-2.

c. Hazardous substance process management (HSPM)

approval - IECQ QC 080000, IECQ 03-5.

2 Supply Chain Services

a. Manufacturer approval

(MA) - ISO 9001, IECQ 03-2.

b. Distributor approval (DA)

- ISO 9001, IECQ 03-2.

c. Sepecialist contractor

approval (SA) - ISO 9001, IECQ 03-2.

d. Counterfeit avoidance program (CAP) approval

- AS 6171, AS 5553, AS 6081, AS 6496, IEC 62668-1, IECQ 03-7.

e. Electrostatic discharge (ESD) approval

- IEC 61340-5-1, IECQ 03-2.

f. Important to nuclear safety (ITNS) approval - ISO

19443, IECQ 03-2.

g. Information security management system (ISMS) approval

- ISO/IEC 27001, IECQ 03-2.

h. Aerospace defense and high performance (ADHP)

approval - IEC 62239-1, IEC 62239-2, IEC 62647-1, IEC 62402,

IECQ 03-4.

3. Component Product Services

a. Qualification approval (QA) -

IEC 60068, IEC 60065, IEC 60115, IEC 60127, IEC 60335, IEC 60339, IEC 60384,

IEC 60598, IEC 60950, IEC 61051, IEC 62321, IEC 62326,

IEC 62368-1..., IECQ 03-3.

b. Capability approval (CA) - IEC 60068, IEC 60065, IEC 60115, IEC 60127, IEC

60335, IEC 60339, IEC 60384,

IEC 60598, IEC 60950, IEC 61051, IEC 62321, IEC 62326,

IEC 62368-1..., IECQ 03-3.

c. Technology approval (TA) - IEC 60068, IEC 60065, IEC 60115, IEC 60127, IEC

60335, IEC 60339, IEC 60384,

IEC 60598, IEC 60950, IEC 61051, IEC 62321, IEC 62326, IEC

62368-1..., IECQ 03-3.

d. Automotive qualification program (AQP) approval- IECQ

03-3, IECQ 03-3-2, AEC Q100 series, AEC Q200 series,

IEC 60068 series....

e. Light emitting diode (LED) lighting approval - IECQ 03-8, IEC 60068.

f. Internet of things (IoT) approval - IECQ 03-3, Wi-Fi relevant standards.

g. Independent testing laboratory

(ITL) approval - ISO/IEC

17025, IECQ 03-6.

II. Maintaining IECQ Certification

Once the companies or laboratories finish the IECQ certification, they are responsible for maintaining IECQ Certification to earn their reputation.